COLD PRESS OIL MACHINE

EVERYTHING ABOUT THE COLD PRESS (OIL PRESS)

In this article, we have tried to examine all the cases related to cold press oil extraction work – selection and purchase of cold oil press machine – effective factors in cold-pressed oil production work, etc.

WHAT IS COLD OIL PRESS?

The cold press is a method of producing oil from oilseeds. Separating oil from oil seeds using pressure without adding chemicals and heat is called cold press.

In the past, oil was separated from grain by the traditional system of milling oilseeds, but with the advent of mechanical press systems, a change occurred in this industry.

Over time, a variety of oil extraction machines were designed and built. Today, these machines are produced in different designs and technology in the press part.

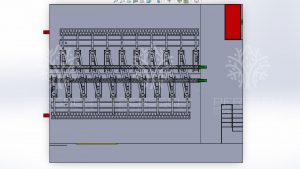

Oil press machines have a press set consisting of cylinders and screws, and parts for adjusting the pressure.

In oil production by cold pressing method, direct heat is not given to the oil and seeds and the approximate temperature of oil extraction is about 40 ° C. This preserves all the beneficial properties of the oil.

Cold pressing method is used to produce various edible and medical oils.

Cold press is also known as oil press – cold oil press – cold pressing – cold press oil extraction – cold press oil – oil pressing and etc.

WHAT IS HOT PRESS?

As mentioned in the cold press oil production method, the oil temperature is about 40 degrees Celsius, but in the hot press method, there is no sensitivity in the oil production temperature and the oil extraction temperature may exceed 100 degrees Celsius.

Usually, oils produced by the hot pressing method cannot be consumed without refining and adding chemicals.

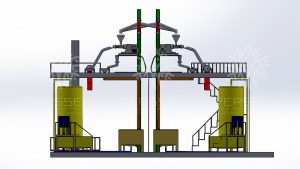

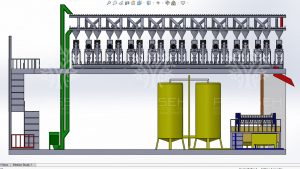

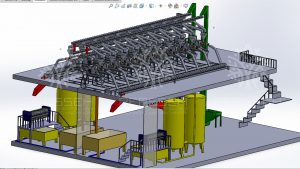

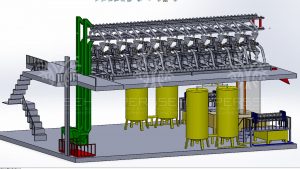

WHAT IS THE EQUIPMENT NEEDED TO SET UP A COLD PRESS OIL EXTRACTION LINE?

Production capacity – automatic and semi-automatic production line – the type of oil for production are the main determining factors for the selection and use of equipment to operate the cold oil press line.

Also, careful study of the space used to produce cold press oil and the basic design of the cold oil press line has a great impact on the optimal and correct selection of equipment.

In low capacity cold press oil production units, the cold press machine is the main tool, feeding the machine and transferring productions is manually

Required equipment in Cold oil press factories:

The design and the production capacity of the cold press line determine the needed equipment

But in general, oil press lines usually have the following cases:

-Unpressed seed tanks

-Seed transfer conveyors

-Cold press machine

-Oil transmission lines and pipes

-Oil tanks

-Filter press machine

-Seed cake transfer conveyor

WHAT PRODUCTS CAN BE PRODUCED WITH A COLD PRESS MACHINE?

A cold press machine must be able to extract oil from a variety of oilseeds.

Factors that make this possible are the design of the cold press machine, the variety of machine settings (speed-pressure-temperature being adjustable), and the power of the machine.

In general, you can press all oilseeds and plants which oil is extracted by pressing.

Today, more than hundreds of types of vegetable oils are produced using these machines.

Meal (Oil cake) is another product of the cold press machine …

The output of the oil press machine is not just oil, the pressed seed (meal – oil cake – cake) is a product that has many users that should not be ignored at all.

The appearance of the meal depends on the press part system of the cold press machine

Due to the high volume of nutrients and also the lack of use of chemicals, this cake can be used in various industries such as the production of food supplements – pharmaceutical industry – food industry – animal feed and so on.

WHAT FACTORS AFFECT THE COLD OIL PRESSING WORK?

One of the most important issues that owners of the oil pressing industry should pay special attention to is the answer to the question of what factors can affect the cold press machine working.

As mentioned, cold pressing work is a completely mechanical work and depends on factors such as area climate, oilseeds type, seed oil percentage, seed moisture percentage, oilseeds dimensions, cleanliness, and dust in the seed.

Also, it depends on the type, power, and design of the oil press machine, the settings of the device, and the amount of knowledge and experience of the operator.

What is the effect of area climate on cold pressing work?

Weather and climatic conditions are the important factors that are less considered and this causes the wrong choice to buy cold oil extraction machine.

The result, in addition to the difficult operation of the cold press machine, leads to a lack of standard efficiency in terms of quality and percentage of oil produced.

For example, hot and dry weather causes oilseeds to lose some of their moisture.

Excessive dryness of the oilseeds causes excessive friction in the press part and the heat increase.

If an unsuitable device is selected in these conditions, the result will be the production of high heat oil and also the loss of a significant amount of oil through the output cake (meal) of the cold press machine.

Or for cold pressing work in wet areas, high humidity will increase the oilseed’s moisture. This excess moisture, in addition to wasting some of the oil in the oil cake, causes a significant increase in suspended particles inside the produced oil.

Increasing these suspended particles will multiply the oil filtration work and as a result, in addition to the high production effort, the production costs of cold-pressed oil will increase.

These are some of the effects of the weather on cold pressing work, and if you do not pay attention to them and choose the unsuitable machine, you will face predictable problems.

WHAT IS THE EFFECT OF OILSEEDS ON COLD-PRESSING WORK?

Before examining the effects of oilseed on the operation of the cold press machine, you must find the answer to a fundamental and very important question.

Is the method of extracting oil from the seed you are considering cold press or not ??

For example, for extracting oil from oilseeds such as sesame, canola, sunflower, black seed, almond, hazelnut, walnut, pistachio, coriander, coconut powder, grape seed, pomegranate seed, pumpkin seed, tomato seed, and hundreds of other seeds is using the cold pressing method.

What is the effect of oilseeds dimensions on cold press oil extraction?

This affects the entry of grain into the machine.

It should also be noted that the press set of the machine be able to crush the grain.

What is the effect of oilseed oil percentage on cold press oil extraction?

Usually, the amount of oil in the seed is inversely related to its firmness, for example, pomegranate seed contains an average of about 5 to 10% of oil, this seed is in the category of hard seeds.

The most important thing to pay attention to is the appropriate settings of the cold press machine’s press set for each grain model. For example, the pressure settings for oil extraction from sesame, which contain about 50% oil, are different from those of pomegranate seed.

If proper settings are not made for one type of oilseed, it will have the following results:

Wasting oil

getting stuck the press parts of the machine

Decreasing oil quality

Increasing oil temperature

Increase the depreciation of parts of the press set of the cold oil press machine

What is the effect of using clean and high-quality grain in lubrication work?

The use of quality seeds, in addition to producing a quality product, greatly increases the useful life of parts.

For example, if you use a grain with dirt and crushed stone, in addition to a sharp drop in the quality of the oil produced, it will increase the friction of pressure and temperature inside the press set.

This article will be updated every 3 days and will be added new content.

COLD OIL PRESS MACHINES

HOW TO CHOOSE A SUITABLE OIL EXTRACTION COLD PRESS MACHINE

The main tool for producing cold pressed oil is the cold press oil extraction machine.

To choose the right, you should have some information about its various aspect

This article will be updated every 3 days and will be added new content.